Fully electric assembly machine: from idea to production

Idea

Together with a customer, we took up the challenge to develop an assembly machine that assembles products for the food industry. The demands of the food industry, the short cycle times (one product every second), the (visual) product inspection and large stand-alone time made this project a challenge in which Zest felt like a fish in water. For this project, the customer was completely unburdened: from solving the set challenge, the construction of the machine and the installation on location, the run-up to full production to training the staff, all this was taken care of by the people of Zest. But all this without losing sight of the wishes of the customer: the customer has been actively involved in all important decision making during the project. Thanks to short lines of communication, a personal approach and a flat organization, we were rightfully the extension of the customer.

Concept

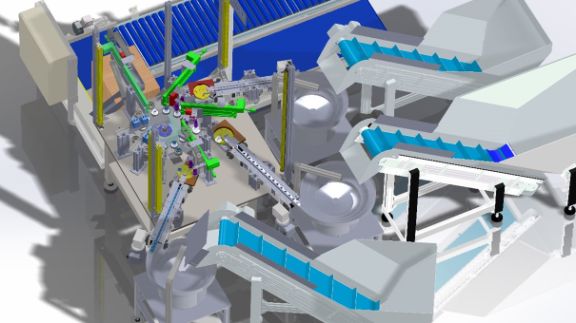

In the concept stage, the customer gained insight into the chosen solutions and it was possible, where necessary, to refine or expand the customer's wishes. All this to deliver a machine that the customer is 100% satisfactory. For the assembly machine, fully electric actuators were chosen: from gripper, sliders, rotary tables to conveyor belts. A total of 24 state-off-the-art SMC electric actuators were used. Initially because of the desire not to use polluting compressed air. An additional advantage is that these actuators can be optimized individually. At the end of the process, all products are checked by 2 times 2 cameras. This is to achieve a consistent and error-free semi-finished and end product. The complete concept was presented to the customer in 3D Solidworks, including simulating the movements of the actuators. All this to give the customer a complete picture of the machine he wants.

Assembly and construction

In addition to developing the idea and presenting the concept, Zest also realized the assembly and construction of the machine on location. All custom-made parts are also designed and developed by Zest, and made by one of our reliable partners. All this was actively led and built by the engineers who were also involved from the idea and concept. All this to put the customer's wishes into practice as well as possible.

Production

The actual running of production for the assembly machine is the most important step for the customer. That is why we also actively provide support to make the step from delivery of the new machine to the (continuous) production run by one of the customer's employees. In addition, we also train the customer's employees to get the most out of the vending machine. We only sign off on a project when the customer is 100% satisfied with the project and the machine is running optimally. After all, it's all about customer satisfaction.