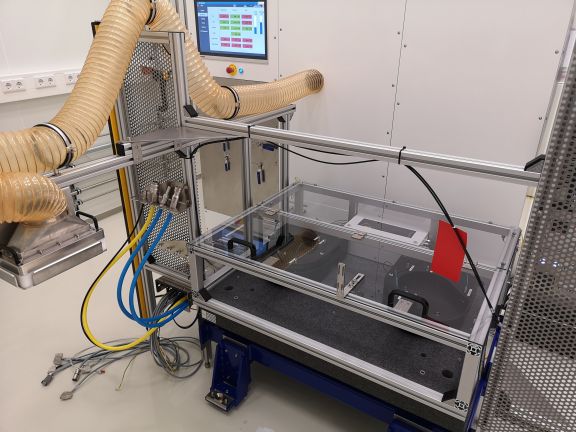

High tech module qualification tool in series production

Especially with complex series production in the High Tech Industry, it is necessary to be able to deliver the same quality every time. Systems must meet the set specifications. With a qualification tool (or Q-tool in short) it is possible to validate whether the system complies with this.

Our High Tech customer in the Semicon builds modules that need to be integrated into a larger whole. However, during qualifying, the "Main Machine" is not present. The Q-tool must therefore also provide all interfaces and facilities so that the module can be qualified as if it were built into the "Main Machine" (final test). This is also the focus of the assignment for Zest-Innovate.

This module has various interfaces, mechanical, electrical, liquids and gasses. Zest-Innovate therefore had to work together with the various module owners and disciplines to ensure that this adjustment runs smoothly. In addition, the module requires various facilities to function, such as different gasses (compressed air, vacuum and ultra clean air), conditioned water cooling, demineralized water for subsequent rinsing and a whole range of electrical signals and sensors.

As an example of one of the interfaces, the mechanical interface consists of a granite stone with waferdocs in which wafers must be laid down by the module with high accuracy. The accuracy with which the module achieves this is one of the qualification requirements. The Q-tool takes care of the control of the module from a simulated "Main Machine" control interface and assesses the accuracy with which the module performs the actions.

In addition, together with the customer, we have ensured that the machine meets the latest machine safety standards and that work can be done safely and ergonomically. This was complex because the module was not designed to work without 'the big whole' and additional security measures had to be taken to comply with this. Safety and easy execution of operator actions is always a coordination. By acting actively with our client on this subject, we are able to correctly weigh both interests.

Due to the increased production and merit of the good collaboration, at the time of writing, Zest-Innovate is working on delivering a second qualification tool.